Brief description

The technology we used is from Germany. We can provide you top level machines with competitive price and perfect services. We are integrated with design, R&D, production, marketing, and after-sales services.

Quick Details

Cihê Origin: Çîn (Mainland)

Navê Pel: EMM

Model Number: DM-402

Piştî xizmetkarê piştî-firotanê: Endezyarên ku ji xizmeta xizmetê xizmeta derve ve

Type: FIPFG formed in place foam gasket manufacturing

Strip width: Micro type: 2-8mm; Standard type: 5-30mm

Technology: Mixing head designed and manufactured in Germany

Dosing system: Barmag metering pump

Control system: Taiwan Syntec CNC system with hand controller

Driving system: Panasonic servo motor

Cleaning system: Water rinsing, built-in the mixing head.

Working speed: 0-12m/s, usually be 6-10m/s

Raw material: Polyurethane, PU, Silicon, other liquid material

Certifications: CE, ISO, RoHS, SGS, CQC, etc.

Product Description

2 components EMM automatic PU foam sealing gasket making manufacturing machine

Ev pispor du herdu materyalên hev re tevlihev dike û bi pêşiya rêzê, groove, moz, an jî zeviya avê ya kargehê û rasterast dakêşin. Bi rêya reaksiyonê kîmyewî, materyalên mîkrofê di sêlên sêlikê de çêbikin. Vê hevbeş an an qutê tune ye, da ku hûn bi awayekî din re bandora wê ya sealandinê bi hev re baştirîn û bi dirêjtir bi jiyanê re ye. Û, di dema pêvajoyê de, pişka çermê gelekî bêkêmasî û bêyî şikilî bûye, da ku bandora xwe ya berbiçav e. Û, ji ber ku ew dikare li ser karmendê xwezayî û bi zûtirîn, nikare karkerek zehmet hewce ne, hewceya mezin ji kar û wextê xilas dibe.

Amûrên kêlîkên Foam bêtir li zeviyên cûrbekirî, wesayîtan, wesayîta motor, pîşesaziyê, hûrgelan, hûrgelan, hûrgelan, hûrgelan, hanê şewitandin, şahidiya avê, damping, dengê şaş û hûrgelan e. bi sertîfîkayên mîna UL / CE, MIL-STD-167, EN50298, û vî awayî.

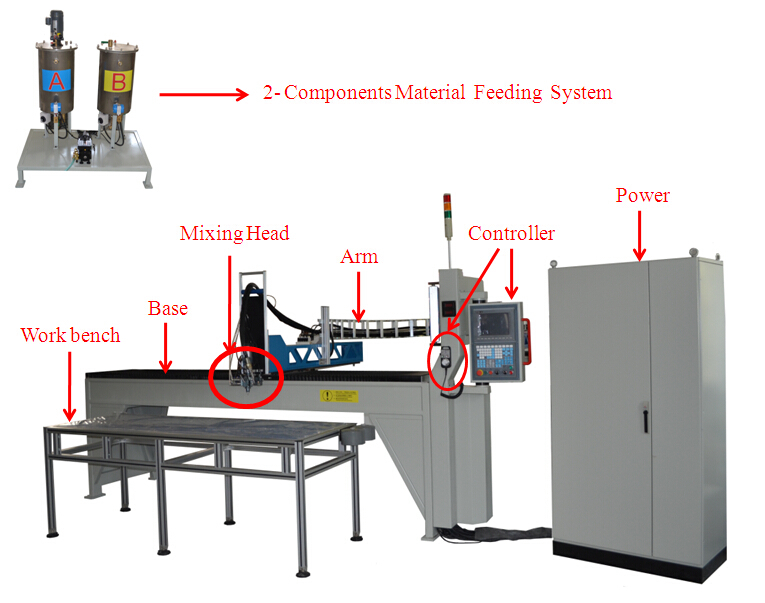

Gasket making machine Construction:

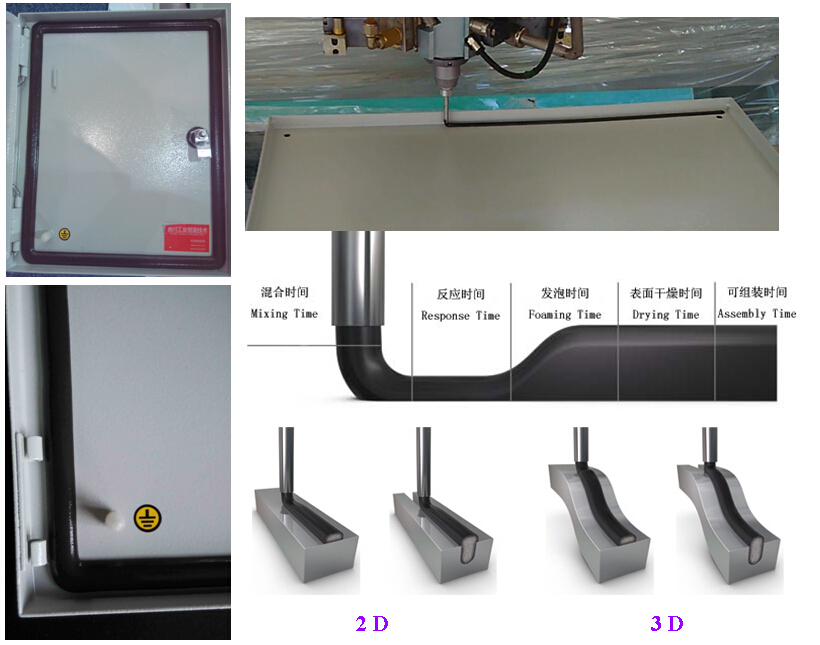

Gasket making machine Raw Material Reaction Principle:

Gasket making machine Main Parts

1. Daxistina Serê:

Water Rinsing & Modular Design

2- / 3- Sîstema tevlîhevkirina tevlihev a bi pergala rînîngê ya avê û pergala dînamîkî ya dînamîkî, ji bo bikaranîna materyalên polîtîk ên ji bo gazketinê, gluing û potting.

2. Pergala Operasyona

Pergala CNC ya ji SYNTEC, 180-degree dravî, Bişkojka pir-zimanî, Agahdariya pir-pir-tê bikaranîn, bernameya USB-Plus û programa G-kodê, operasyonê ji bo bijartinê jî, hêsan tê bikaranîn.

3. Barrên Raw Material:

Double-stainless steel stainless steel, automatic temperature control.

4. Biryara xebatê:

Alloyek aluminum, bihêz û bihêz.

5. Sîstema Dosing:

Pumpirê metering Barmag, Motor bike Panasonic, Microscale gluing workable.

6. Hand Controller:

SYNTEC, bi hêsanî kontrol bikin, bersiva lez û lezgîn.

7. Sîstema ajotinê:

Panasonic motor, motê kar, dirêjkirina karanîna dirêj, dikare ji bo dehan saetan berdewam bimînin.

Our Gasket making Machine Equipment Advantage:

| Our Company, Jinjie | Some other companies | |

| Teknolocî | From German, top level, mature and stable | R&D in China, Chinese level, in developing |

| Tevlîhevkirinê | Made in Germany (Germany manufacturing and processing technology, and quality) | Made in China, Chinese quality. |

| Mode Kar | 2D or 3D for choice (could process special 3D patterns) | 2D only |

| Mode Control | 8 axis linkage as a whole (1X+1Y+1Z+2Mixing+2Reserved, Could adjust & change to 3-components equipment or adding auto material feeding system according to needed.) | 3 axis + other control systems, need matching |

| Gluing Width (Standard type) | 5-30mm | 8-30mm |

| Gluing Width (Micro- type) | 2-8mm | 3-8mm |

| Repeat Positioning Accuracy | +/-0.03mm | +/-0.05mm |

| Dosing | 0.5~5g/s | 1~4g/s |

| Continous working time | can keep working for a whole day (there is a special coating on the mixing head to prevent residual) | Frequently temporarily stop for cleaning residual |

| Processing capability of factory | machine shop belongs to ourselves, Jinjie | Processed by another company, then assembled in another place. |

| Offer | Very competitive | Higher |

Gasket making machine Standard type equipment specifications:

| Specification Technical | Hinek agahdarî | |||

| Armê Mîkî | 6 * 3 m | Teknolocî | Ji Almanya | |

| Karker | 2.4 * 0.9 m | Tevlîhevkirinê | Ji Almanya | |

| Bench Material | 1.2 * 0.85 m | Emelî | Ji Titan Syntec, pergala CNC | |

| Stroke Kar | 2.4 * 1.2 * 0.25 m | Hand Controller | Ji Taiwanê Syntec | |

| Gluing Width | 5-30 mm | Motor | Panasonic Servo Motor | |

| Gluing Precision | 0.01 mm | Metering Pump | Ji Almanya, Barmag | |

| Speed Speed | 0-12 m / min | Paqijî | Risining Water | |

| Max Speed | 30 m / min | Barrels | Double-stainless steel stainless steel, automatic temperature control | |

| Repeat Positioning Accuracy | +/- 0.03 mm | Mode Control | 8 girêdan axis, 1X + 1Y + 1Z + 1mixing + 2metering + 2 refererving | |

| Dosing | 0.5-5 g / s | Mode Kar | 2D an 3D | |

| Filling Accuracy | 0.1 g / s | Rengê sereke | Zêrîn spî, wêneyê reş, an jî reş, sor, sor. bin gotûbêjan. | |

| Lezkirina Tevgera | 0-3000 rad / min | Custom-made, OEM, ODM | OK, pirsgirêk tune. | |

| Rêjeya Tevlîhevkirinê | 1: 10 ~ 10: 1 1 | Sertîfîkayê | CE, RoHS, ISO, etc. | |